Upgrade Pump Room Equipment

Exclusive Website Content

It improves an aquatic facility and the bottom line

By Mike Fowler

Service professionals know if an aquatic facility was not built recently, chances are the pump room could probably use an upgrade. Strategic improvements can enhance the ‘feel and smell’ of a pool environment. Existing facilities can drastically reduce their operating costs by upgrading pumps and heaters as well as improving the water and air quality by adding controllers and ultraviolet (UV) systems. Service professionals are helping aquatic facility managers take advantage of energy rebates and incentives by evaluating the pool room as a whole so every component runs with greater synergy. Further, by upgrading to energy-efficient, technologically advanced equipment, facilities can provide a better, safer, and healthier environment for bathers and swimmers.

Rebate Alert

Older pumps with induction motors only operate at one or two speeds and, as a result, draw more energy than is required to circulate pool water. These units must constantly operate at high speeds in order to perform the pump’s most demanding jobs (e.g. running a waterfall or pool cleaner). However, it takes far less power to simply keep the water filtered—a difference single-speed pumps cannot address.

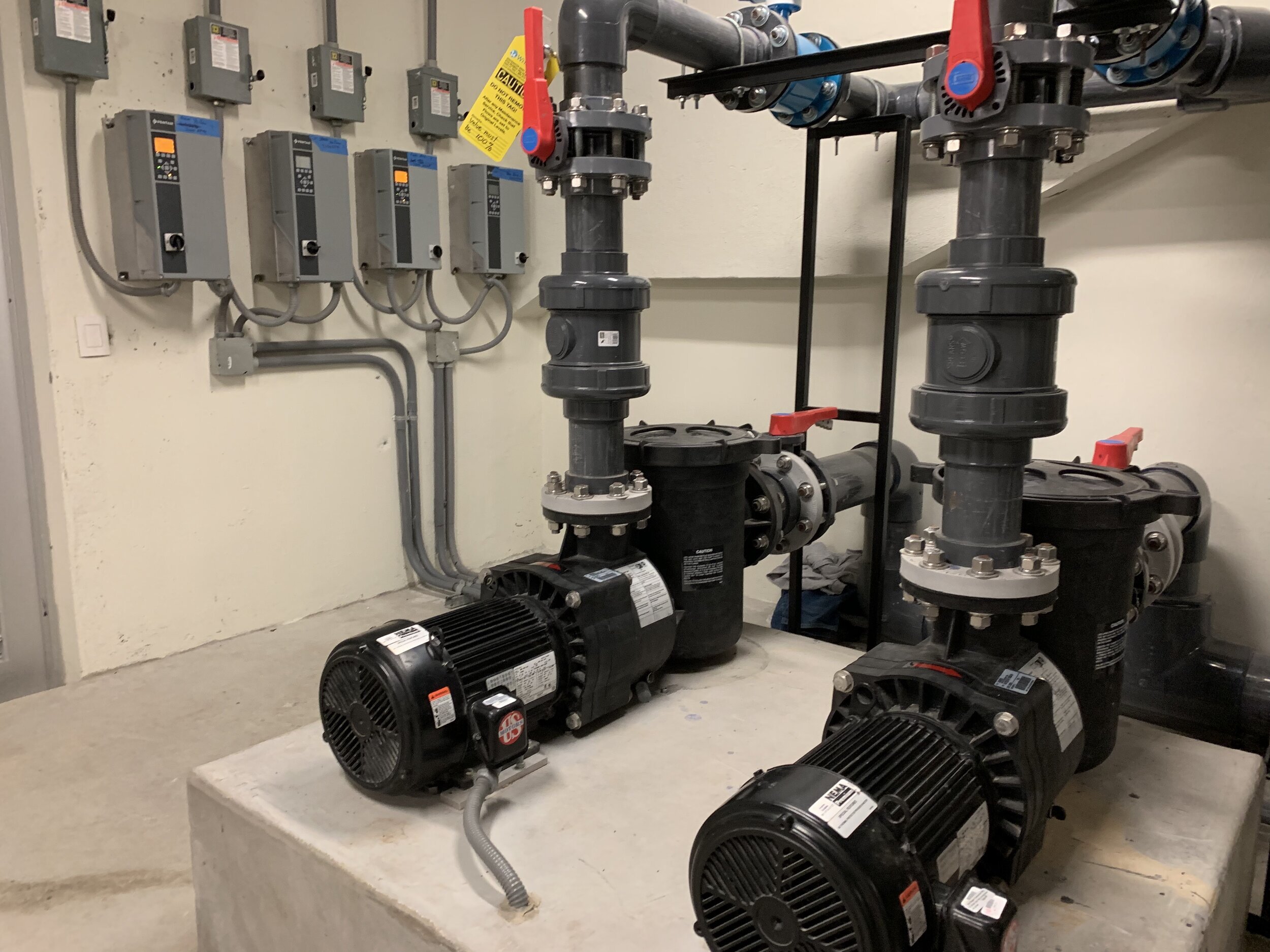

Variable-Speed Pumps

Newer variable-speed pumps (VSPs) differ in their ability to be programmed to operate at set speeds so they can deliver the correct flowrate for each task they perform. This characteristic enables facilities to reduce energy consumption and increase savings. These pumps can also be programmed to achieve turnover times of exactly six hours, even if the filter is dirty. This allows motor speed, power, and energy to be reduced during times when the filters are clean, instead of sizing the pump to assume worst-case operating conditions.

Some VSPs even have built-in, constant-flow software, which maximizes the advantages these units have to offer, as the program automatically adjusts the device’s speed to deliver the required flowrate for each programmed task. This means even as the filter accumulates dirt, the pump will sense resistance in the circulation system and automatically increase its speed to continually provide the proper flowrate the water feature requires.

It does not matter what type of pump is being used, slower speeds save energy. This also reduces noise levels, as well as wear and tear on the other equipment the water flows through. Also, in some areas VSPs are eligible for rebates and other incentives provided by local utilities. Therefore, facility operators must check with these companies to help offset the cost of a new, energy-efficient VSP for the pool.

Variable-Frequency Drives

Specified to save energy, space, and costs, most variable-frequency drives (VFDs) are designed to be the heart of the pump room. With minimal payback time, they provide automatic energy optimization and a built-in direct-current (DC) link reactor that reduces harmonic noise to protect the drive. Some VFDs also offer an initial ramp, which provides pump acceleration to a desired minimum speed. This is when the normal ramp takes over, preventing damage to thrust bearings and overheating of the pump.

“VFDs are quite amazing,” says Richard Deakin, commercial product development manager at Hollandia Gardens Inc. “Many facilities where we installed these drives have achieved an electrical cost savings of more than $10,000 per annum,” says Deakin. “The units aren’t free, but the payback is normally less than 18 months. Some municipalities are even providing rebates from utility companies, which makes the payback period even shorter.”

Upgrading Heaters For Greater Efficiency

Aquatic facilities can also reduce operating costs by upgrading to a new, high-efficiency heater. Older models from seven to10 years ago may have started out being about 78-85 per cent efficient. However, over time, the same heaters will only be about 60 per cent efficient—as heat exchanger tubes fill with buildup, and the burners get clogged, too. That said, newer models have higher efficiencies. Today’s heaters are range in the low to mid 90 per cent efficient (and some direct-fire models have efficiencies up to 95 per cent). As a result, these units consume less energy and will immediately lower electricity bills. Additionally, newer heaters are easier to operate, and produce lower emissions, resulting in better air quality in the pool environment.

There are a few reasons for decreased efficiency of heaters.

Buildup on heat exchanger tubes

This is the most common reason for decreased efficiency. When heat exchanger tubes build up with chemical residuals and calcium, it causes the unit to lower its water flow. This, in turn, causes the device to consume more energy to heat the same amount of water in the pool.

Condensation

When burned, propane and natural gas produce water as a byproduct. The combustion is then compromised because ‘raining’ condensate interferes with the flame pattern. This condensation causes inefficiencies in the heater functionality.

As mentioned earlier, in addition to operating more efficiently and lowering costs, upgrading pool heaters offers several other benefits.

New heaters are designed to be ‘low nitrous oxide (NOx)’ units with minimal emissions, which is one of the main advantages of using improved equipment. Low NOx heaters are environmentally friendly as their nitrous oxide emissions are below 10 per cent. In some provinces, these units are required to have a regulated emission standard.

These heaters are also easier to maintain as they are designed with ‘plug-and-play’ functionality. This can be extremely advantageous, especially because many installers are not trained in commercial application techniques. Further, aquatic facilities find pool cleaning staff, lifeguards, and managers adjusting heater settings frequently. Therefore, having a unit that is completely enclosed and ready-to-go, leaves less room for problems caused by staff members.

Finally, new heaters have sealed combustion units, which make them safer to operate. Most units installed indoors are often located next to stored chemicals. If sealed, these devices are less of a fire hazard (even if chemicals are not present when the heater is installed, they might make an appearance later). Further, these devices also ensure adequate combustion air is available as the outside air is ducted with a sealed combustion unit.

Automation Help: The Controller

Facility operators must be aware that poor water can lead to low air quality. The latter can be a combination of improperly maintained water chemistry, an insufficient filtration system, and a non-functioning air-handling system. These are the typical reasons why chlorine molecules in pool water lose the battle against bacteria and give way to chloramines (NH2Cl), filling the indoor aquatic environment with bad-smelling, eye-irritating air.

If there is an insufficient supply of free available chlorine (FAC) to the pool, the existing chlorine combines with contaminants in the water to create NH2Cl. This process results in off-gassing, which is released into the air at the surface of the pool. It can also become trapped in the moisture that is evaporating to create a toxic soup in and around an indoor facility. Not only is this gas hazardous for swimmers (and all the people in the facility), it can also corrode the dehumidification system(s) and other pump room equipment.

Game-Changer: UV System

An appropriately sized UV system should be installed in the pump room to enhance the water and air quality. Most commercial facilities are upgrading their equipment rooms with medium and low pressure UV systems, which not only eliminates chloramines, but it also offers a secondary sanitation system that provides cleaner, clearer water.

Once the UV system is installed, chloramines are virtually eliminated, and the air is cleared within 24 hours. In addition, the unit contributes to reducing the facility’s operating costs as 30 to 40 per cent less chlorine is being used.

“UV systems have become a real game-changer for existing facilities that want to upgrade the overall quality of their aquatic environment,” says Deakin. “The change is felt immediately by staff and pool users, thereby helping to improve overall working and swimming conditions.”

In the long term, the reduced chloramines also lessen corrosion to the equipment. Therefore, as part of the improvement process, the installation of an automatic controller is paramount. The device provides automated control of the pool’s pH and oxidation reduction potential (ORP) levels, which help to stabilize the water and reduce the over-consumption of chemicals. By monitoring and treating water 24-7, facilities avoid excess use of chemicals caused by high-and-low chemical levels and dosing. Further, by ensuring proper chemical balance and treatment, the facility will also benefit, indirectly, from better air quality.

Benefits Of Upgrading

Technological advancements in today’s equipment make it imperative that pool operators are achieving the water quality, parameter reporting, and cost controls necessary to keep facilities running smoothly. With the substantial energy-use rebates being offered by local power companies, in conjunction with the savings in daily operational expenses, some end-users are getting back approximately 50 per cent of the pump’s cost in less than a year. Service professionals are in a unique position to help facilities reap the many benefits of upgrading equipment in the pump room. Improving the aquatic environment can also lower operating costs and reduce the environmental impact of the facility. Also, pool professionals can profit from new equipment sales and also earn increasing customer loyalty with the facility.

About the author: Mike Fowler is a commercial sales manager for Pentair in Sanford, N.C. He has been with the company since 1992, starting his career in the technical services department at Purex Pool Products. Fowler has held many managerial roles within the company, including marketing, accounting, and products. He can be reached via email at mike.fowler@pentair.com.